Exploring the World of Mylar Bags: Printing Processes and Their Benefits

Share

Introduction

In the world of food storage and preservation, Mylar bags have emerged as a popular choice due to their exceptional capabilities. They offer a wide range of benefits, including being smell-proof, which is crucial for keeping food fresh and safe. In this comprehensive blog post, we will delve into the fascinating realm of Mylar bags, focusing on the four different printing processes they can undergo. But first, let's understand what smell-proof Mylar bags are and why they are essential.

What are Smell-Proof Mylar Bags?

Smell-proof Mylar bags are specialized food storage containers designed to prevent odors from escaping or entering the bag. They are typically made from a combination of Mylar, a type of polyester film, and aluminum foil. This unique construction creates a barrier that effectively seals in the aroma of the contents, making them ideal for storing aromatic or perishable items.

Why Do We Need Smell-Proof Mylar Bags? What are the Features?

- Ensuring Freshness and Flavor

- Extending Shelf Life

- Protecting Sensitive Items

- A Versatile Solution

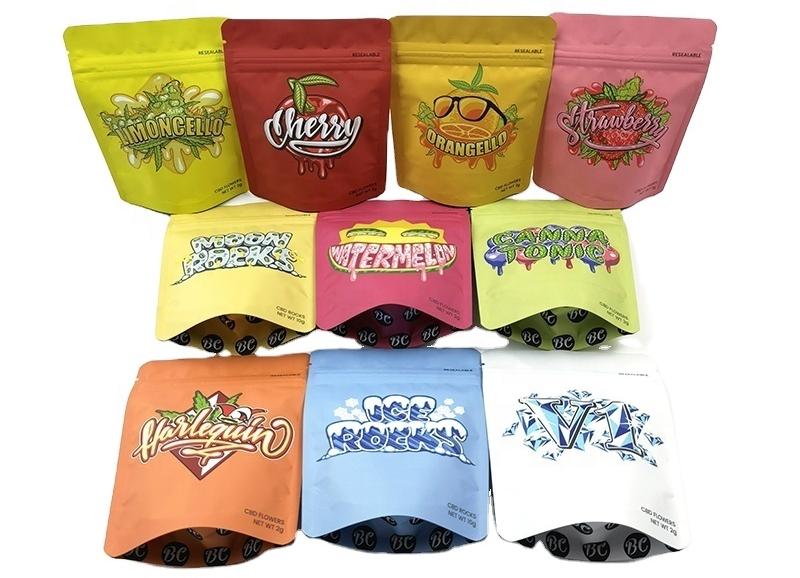

The versatility of smell-proof Mylar bags extends beyond food storage. They are also used in various industries, including cannabis packaging, where odor control is paramount for compliance and discretion.

Four Surface Printing Processes for Mylar Bags

Now, let's dive into the exciting world of Mylar bag printing processes. Mylar bags can undergo various surface printing techniques, each with its own unique characteristics and applications.- UV Printing

UV printing, short for ultraviolet printing, is a high-resolution printing process that uses ultraviolet light to cure inks instantly. It offers vibrant colors and sharp details, making it ideal for intricate designs and logos on Mylar bags. UV-printed Mylar bags are known for their durability and resistance to fading, making them suitable for long-term storage and display purposes.

- Glossy Printing

Glossy printing creates a shiny, reflective surface on Mylar bags. It enhances the visual appeal of the packaging and provides a luxurious finish. Glossy-printed Mylar bags are often used for premium products and gifts. The reflective nature of the surface can also help draw attention to the contents, making them ideal for retail packaging.

- Matte Printing

Matte printing, on the other hand, creates a non-reflective, smooth finish on Mylar bags. It exudes a subtle elegance and sophistication, making it a popular choice for packaging items where a subdued aesthetic is desired. Matte-printed Mylar bags are also less prone to showing fingerprints and smudges, maintaining a clean appearance.

- Holographic Printing

Holographic printing adds a mesmerizing and iridescent effect to Mylar bags. It creates shifting patterns and colors when viewed from different angles, making the packaging visually captivating. Holographic-printed Mylar bags are often used for products that aim to stand out and make a statement on the shelf.